Green technology

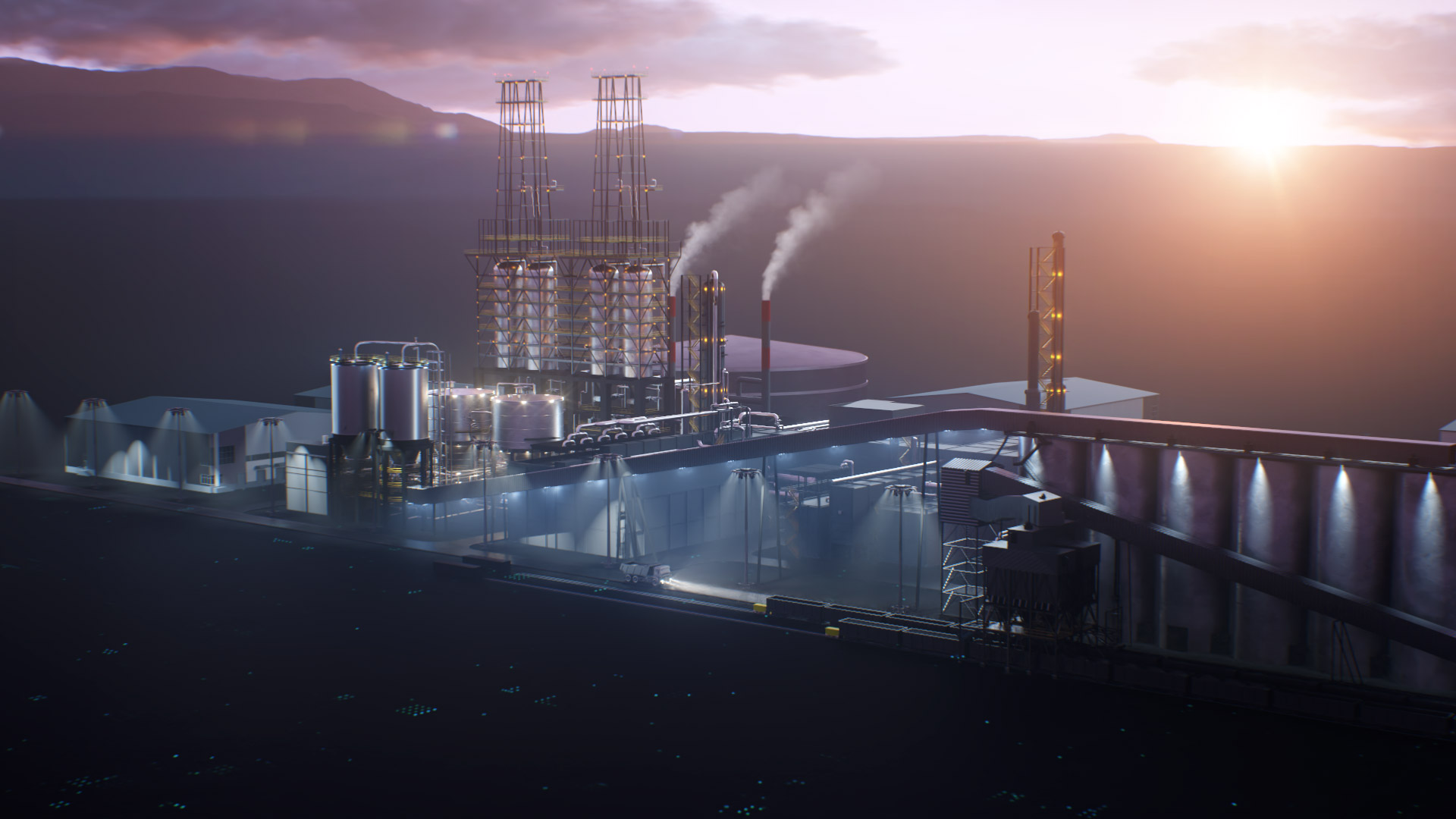

Today green focus is a key feature of social responsibility of the company. Problem of the ecological impact caused by refineries operating in Russia is a challenge we are ready to face.

Environment pollution is the global problem

Main Earth ecology problem is air pollution. One of the main pollution source is oil refineries.

Most of the gases discharged by the refineries to the atmosphere are harmful for environment. A lot of refineries are located in the cities and towns or nearby them, their emissions have adverse impact to citizen's health.

Russia is a world leader in oil production and refining

In 2019 alone, Russian oil market players have refined more than 250 mln. tons of crude oil and condensate in Russia.

Data from companies official websites for 2019.

Our mission is to minimize environmental impact caused by the refineries

CCSS technology reduces emission of hazardous substances to the atmosphere by 99.9%. It is the most ecological method to handle petroleum coke of existing nowadays.

Basis of the technology is a principle of inline crushing of wet coke and its processing to the slurry condition. It allows to handle and dewater coke in a closed system of pipelines and vessels. This ensures that the level of hazardous emissions to the atmosphere is reduced significantly without refinery efficiency losses.

Closed system operation principle

Coke feed to the coke crusher through a special transition piece that compensates thermal expansion and coke drum vibration.

In-line crushing during cutting.

Crushed coke with water mixture feed to the slurry basin through the sluice ways.

Coke slurry transfer to the dewatering bin using special pump.

Coke and water separation by special internals of the bin that trap more than 99.5% of fines.

Marketable coke loadout from the dewatering bin to the belt conveyor.

Remaining water drain from the vibrating feeder to the dirty water pit. After that water returns to the slurry basin through closed system.

Water drain from the dewatering bin to the drain water basin.

Water with coke admixture feed to the settling tank for final coke fines settlement.

Discharge of deposed coke fines to the slurry basin.

Water feed to the clean water tank for final cleaning, after that water is used for further operating stages in the closed system.

Performance comparison of the technologies

Production ecological safety2

Dewatering efficiency

Water saving

Automation level

Operational expenses savings

Production safety

Until 2006 there was only open method of coke handling.

Reduction in coke fines and volatile organic compounds emission.

CCSS technology key features

Video presentation of the coke handling system using CCSS system

Catalog

Turn-key and customized equipment